PLATE ROLLING AND FORMING SERVICES

PT Welding

Plate Rolling and Forming Services

PT Welding can cut Carbon Steel, Stainless Steel & Aluminum.

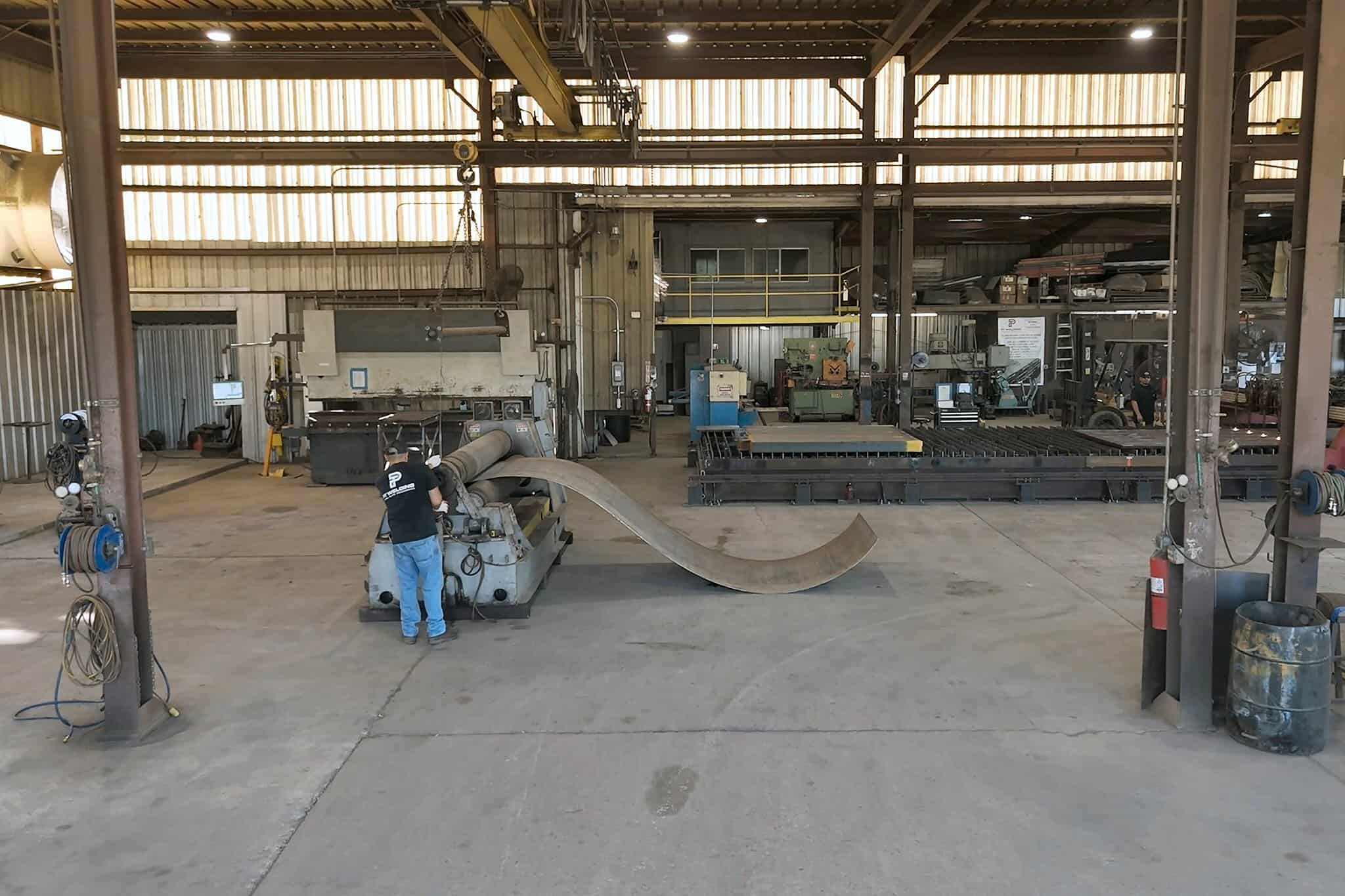

When it comes to needing steel plate rolled into cylinders, formed into cones or many other shapes, PT Welding can handle it all. Whether it’s hot forming or cold forming plate, PT Welding has the expertise to deliver quality products to your specifications.

Our plate rolling and forming process can include plate layout, cutting, beveling, and welding if required. We can also provide assistance in designing your cone to maximize plate usage.

The following plate grades kept in stock:

- Carbon – A/SA36, A572, A633, SA516, SA537, API 2H, ABS EH/DH

- Stainless Steel – 304, 316

- Aluminum – 6061, 5052

Our process begins with a thorough understanding of your requirements. We work closely with you to determine the specific dimensions and shapes needed for your project, ensuring that every detail is accounted for. Utilizing advanced lay-out techniques, we will map out the ideal cutting patterns to maximize the use of your materials. This not only reduces waste but also optimizes cost efficiency for your project.

Once the layout is finalized, our skilled technicians employ state-of-the-art cutting technology, including flame and plasma cutting, to achieve clean and precise edges. We stock a wide variety of plate grades, including carbon steel, stainless steel, and aluminum, allowing us to cater to a broad spectrum of industry applications. From A36 carbon steel to high-performance stainless grades, we have the materials at hand to fulfill your project requirements efficiently.

In addition to cutting, our Plate Rolling and Forming Services extend to the crucial steps of beveling and welding if needed. Beveling is often essential for ensuring strong, seamless joints, particularly in projects requiring structural integrity. Our experienced welders are adept at producing high-quality welds that withstand the rigors of demanding applications.

Hot forming and cold forming are two techniques we specialize in, each chosen based on the material and desired outcome. Hot forming allows for greater flexibility in shaping, making it ideal for thicker plates, while cold forming is utilized for precision and detail in lighter materials. Regardless of the method, our team is well-versed in the complexities of the process and committed to achieving excellence in every product we deliver.

Moreover, our focus on maximizing plate usage goes beyond simply laying out designs. We can assist in the design phase of your cones and other shapes to ensure that the dimensions not only meet your specifications but also leverage the materials in the most effective way possible. This collaborative approach enhances the efficiency of fabrication while still delivering high-quality results.

Our facility also maintains a focus on safety and environmental responsibility. We adhere strictly to industry standards and regulations, ensuring that every process from cutting to forming is executed with the utmost care for both our team and the environment. Investing in modern equipment and technology, we strive to minimize our ecological footprint while maintaining productivity.

As we navigate the diverse needs of our customers, PT Welding remains committed to superior service. Our extensive experience in plate rolling and forming has garnered us a reputation for reliability and quality in the steel industry. We take pride in building strong relationships with our clients, offering not only our processing capabilities but also our consultation and support throughout each project.

Whether you require a single component or a large-scale production run, PT Welding is equipped to handle orders of any size with the same level of dedication and expertise. Our comprehensive plate processing capabilities allow us to manage everything in-house, providing seamless communication and coordination, streamlining the process from start to finish.

At PT Welding, we believe that our Plate Rolling and Forming Services set us apart in an industry filled with challenges. By focusing on customer needs, quality materials, advanced technology, and skilled craftsmanship, we ensure that your projects not only meet but exceed expectations. From concept to completion, trust us to deliver solutions molded to your specifications.

If you’re seeking innovative and efficient plate rolling and forming solutions, we invite you to reach out to our team. Let us help you transform your ideas into tangible products that stand the test of time. With our commitment to excellence in welding and full-service plate processing, PT Welding is your go-to partner for all your project needs. Contact us today, and let us bring your vision to life with our reliable and expert plate rolling and forming services.

Full Service Plate Processing Facility

Equipped with both flame and plasma cutting capabilities, we offer versatile and precise cutting solutions to accommodate diverse customer requirements across various industries. Our extensive inventory includes carbon steel, stainless steel and aluminum ensuring we have the materials necessary to fulfill your project needs efficiently and effectively.

"PT Welding is a specialty steel plate distributor and processor, with a comprehensive inventory of carbon & alloy plate, as well as a wide range of processing capabilities. PT Welding's plate processing capabilities differentiate the company from others in the steel industry, with plasma and oxy-fuel burning, beveling, drilling, tapping, counterboring, countersinking, rolling, forming, and all in-house. PT Welding was built on superior service and quality, and these values continue to define the company today."

OPERATIONS

28500 Calvert Road

Tomball, Texas 77377

BUSINESS HOURS

CONTACT INFO